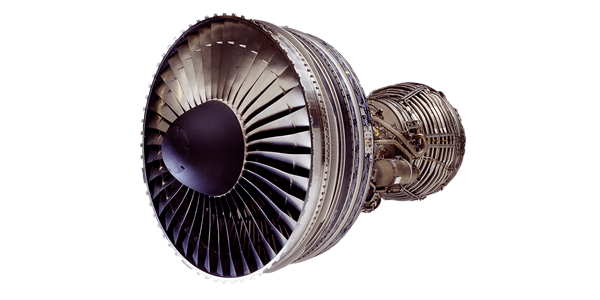

CTS Engines’ technicians are currently training for the highest level of certification to provide MRO services on the PW4000 engine. Please check back in early 2023 for our official release of services on this particular engine type.

Lowering Engine Cycle Costs

- Maintenance and overhead minimized through partnership.

- Enhanced revenue generation through combined special services.

- Truly independent and confidential service objectives to reduce cost, turnaround time, and customer satisfaction.

- Highly trained, professional, and quality-minded technical staff and technicians.

- Immediate field service response AOG situations.

- Customer-oriented technicians and staff experienced with both airframe and engines.

Checklist of PW4000 Overhaul Services

- Removal, replacement, and reinstallation of compressor and turbine blades

- Blade grinding

- HPC/HPT/LPT rotor balancing

- Moment weighing of hand, STC 1+2 HPC, STG 1+2 HPT, All LPT Blades

- Decoking of oil lines

- Vibration/trim balance surveys

- Full module repairs

- QEC swaps

- Fuel nozzle exchanges, worldwide AOG/on-site quick-turn field service support

- On-wing Maximum Power Assurance (MPA) certification

- Borescope inspection and digital measurement

- Borescope blade blending

- Airworthiness Directive (AD) and Service Bulletin (SB) compliance

- Engine removal and installation

- NDI / NDT services

- Engine management, including leasing and trading of spare engines

- Engine QEC reconfiguration, removal and installation

- AD/SB inspections

- All work comes with dual FAA/EASA release forms