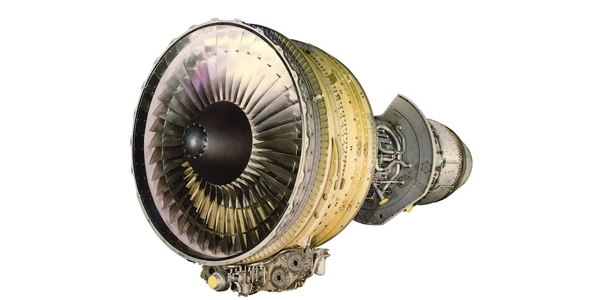

The General Electric CF6-80E1 was specifically engineered for the Airbus A330, integrating advanced technologies to deliver exceptional performance in terms of weight reduction, fuel efficiency, and reliable stall-free operation. Featuring a 96-inch fan and a 4-stage booster with cutting-edge aerodynamics, the CF6-80E1 represents a significant advancement within the CF6 family. Over time, its thrust capacity has increased from 70,000lbs to an impressive 72,000lbs, making it the most powerful engine in the successful CF6 lineage.

Lowering Engine Cycle Costs

- Maintenance and overhead minimized through partnership.

- Enhanced revenue generation through combined special services.

- Truly independent and confidential service objectives to reduce cost, turnaround time, and customer satisfaction.

- Highly trained, professional, and quality-minded technical staff and technicians.

- Immediate field service response AOG situations.

- Customer-oriented technicians and staff experienced with both airframe and engines.

Checklist of CF6-80E1 Overhaul Services

- Removal, replacement, and reinstallation of compressor and turbine blades

- Blade and shroud grinding

- HPC/HPT/LPT rotor balancing

- Top case repairs

- Moment weighing of hand, STC 1+2 HPC, STG 1+2 HPT, All LPT Blades

- Decoking of oil lines

- Shroud grinding

- Vibration/trim balance surveys

- Welding of LPT deflectors, LPT mid frame cracks, LPT hot section cracks, LPT stud and nut retention welding

- Full module repairs

- QEC swaps

- Fuel nozzle exchanges, worldwide AOG/on-site quick-turn field service support

- On-wing Maximum Power Assurance (MPA) certification

- Borescope inspection and digital measurement

- Borescope blade blending

- Airworthiness Directive (AD) and Service Bulletin (SB) compliance

- Engine removal and installation

- NDI / NDT services

- Engine management, including leasing and trading of spare engines

- Engine QEC reconfiguration, removal and installation

- AD/SB inspections

- All work comes with dual FAA/EASA release forms