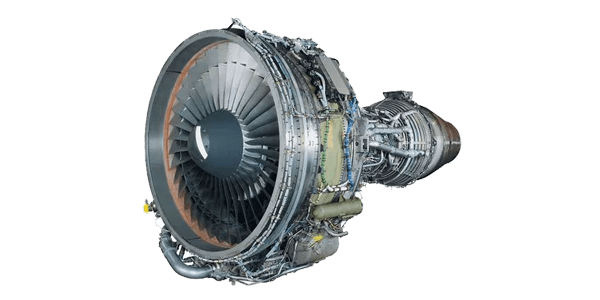

The PW2000 was developed by Pratt & Whitney to power the 757 entering into service in 1984. With 37,000-43,000 pounds of thrust, the technical innovations of this engine type delivered high reliability, low maintenance costs resulting in unparalleled performance at the time. It was also the first engine to offer electronic engine control, also known as FADEC (Full-Authority Digital Electronic Control). With more than 26 million hours of service, the PW2000 is ETOPS certified and can meet the demands of both short and long-haul operations. CTS Engines is proud to offer full-service MRO capabilities for PW2000 operators.

Lowering Engine Cycle Costs

- Maintenance and overhead minimized through partnership.

- Enhanced revenue generation through combined special services.

- Truly independent and confidential service objectives to reduce cost, turnaround time, and customer satisfaction.

- Highly trained, professional, and quality-minded technical staff and technicians.

- Immediate field service response AOG situations.

- Customer-oriented technicians and staff experienced with both airframe and engines.

Checklist of PW2000 Overhaul Services

- Removal, replacement, and reinstallation of compressor and turbine blades

- Blade grinding

- HPC/HPT/LPT rotor balancing

- Moment weighing of hand, STC 1+2 HPC, STG 1+2 HPT, All LPT Blades

- Decoking of oil lines

- Vibration/trim balance surveys

- Full module repairs

- QEC swaps

- Fuel nozzle exchanges, worldwide AOG/on-site quick-turn field service support

- On-wing Maximum Power Assurance (MPA) certification

- Borescope inspection and digital measurement

- Borescope blade blending

- Airworthiness Directive (AD) and Service Bulletin (SB) compliance

- Engine removal and installation

- NDI / NDT services

- Engine management, including leasing and trading of spare engines

- Engine QEC reconfiguration, removal and installation

- AD/SB inspections

- All work comes with dual FAA/EASA release forms